- The world's

- advanced storage

- solutions

-

Adopt outstanding technology and innovative development, to provide large capacity, high performance, reliable and durable storage devices.

Controller & Firmware

Autonomous Control

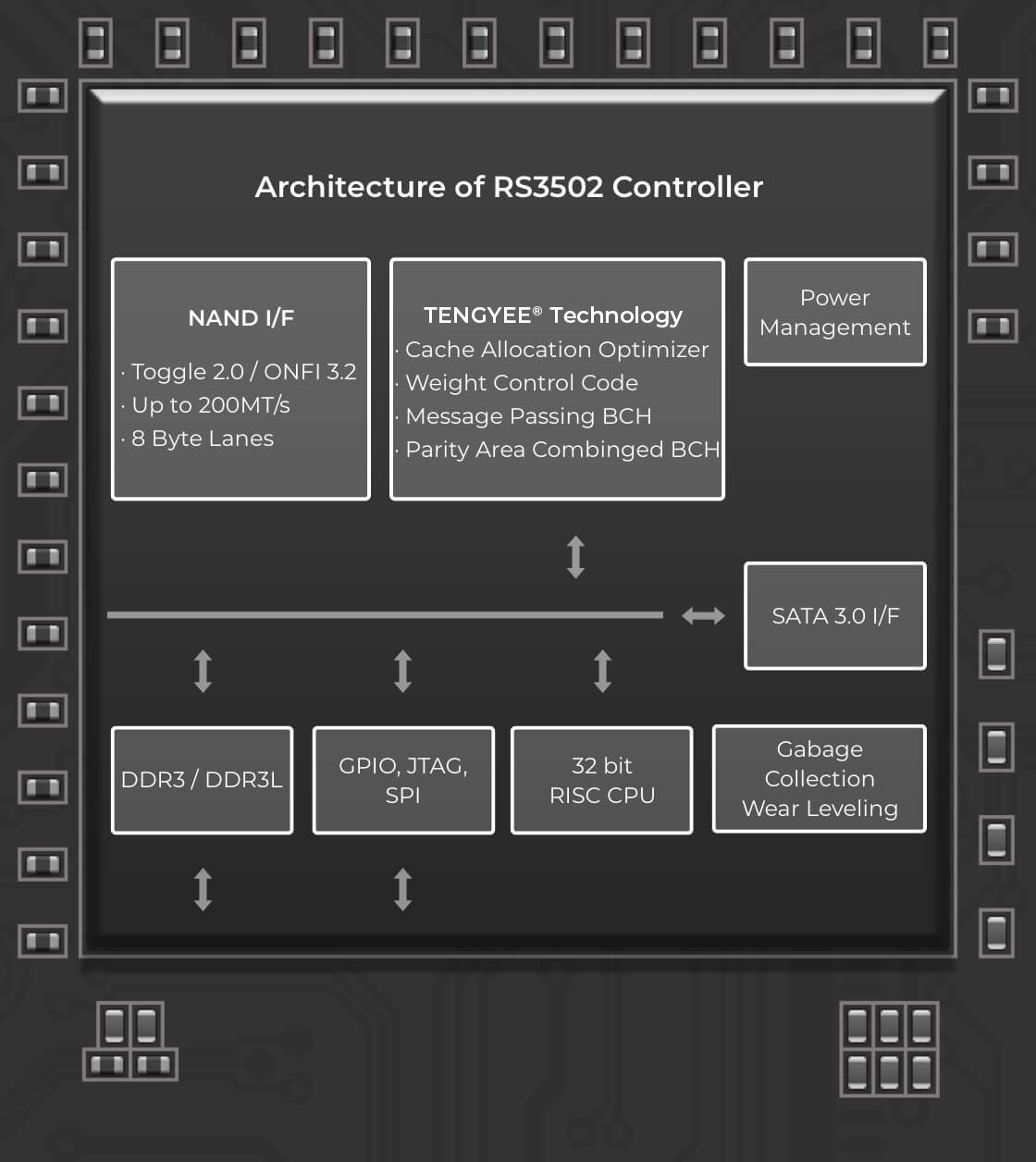

RS3502 Controller – Independent R&D, Focus on industrial Field

-

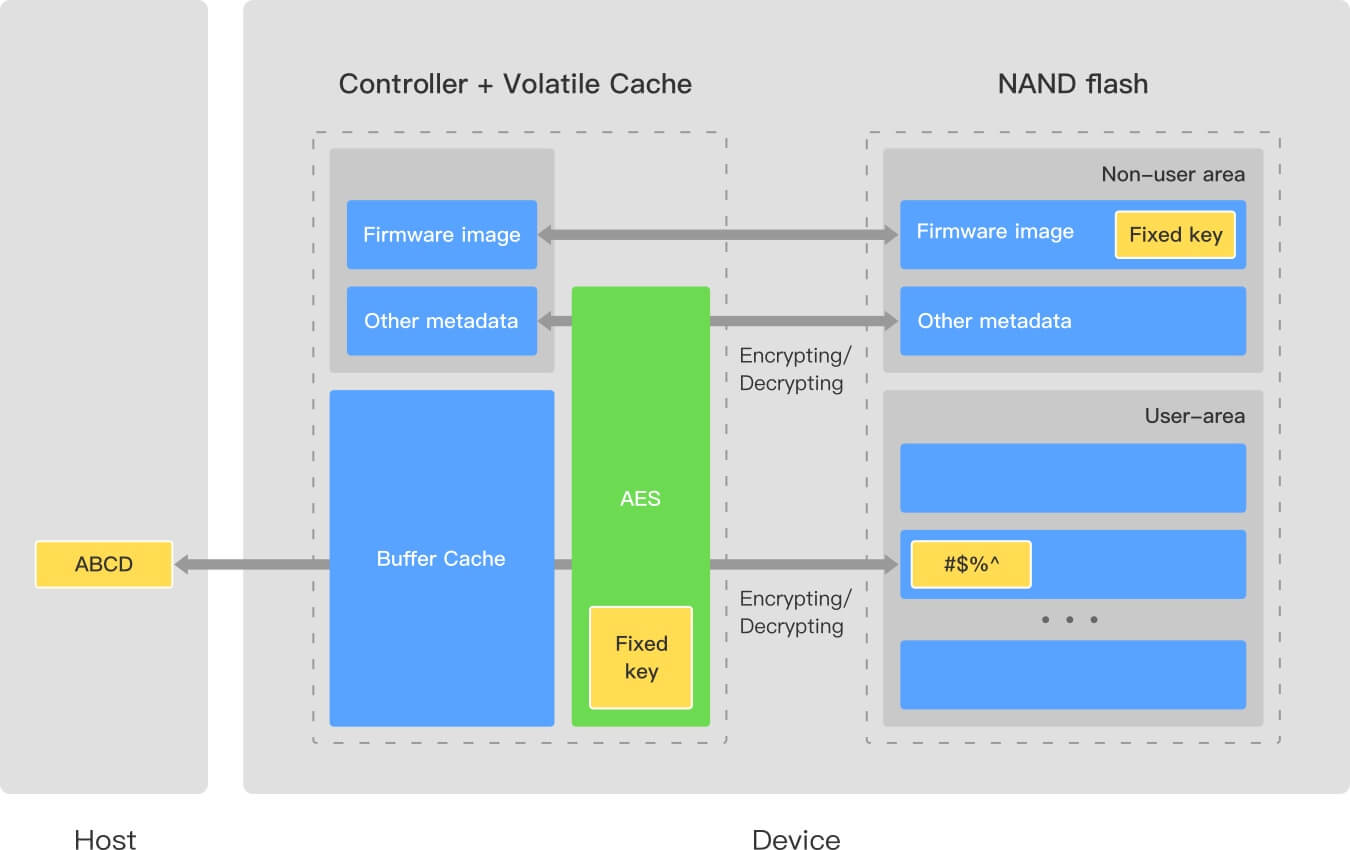

AES EncryptionIn-built 256bit AES encryption,enable for various encryption and erase technology

-

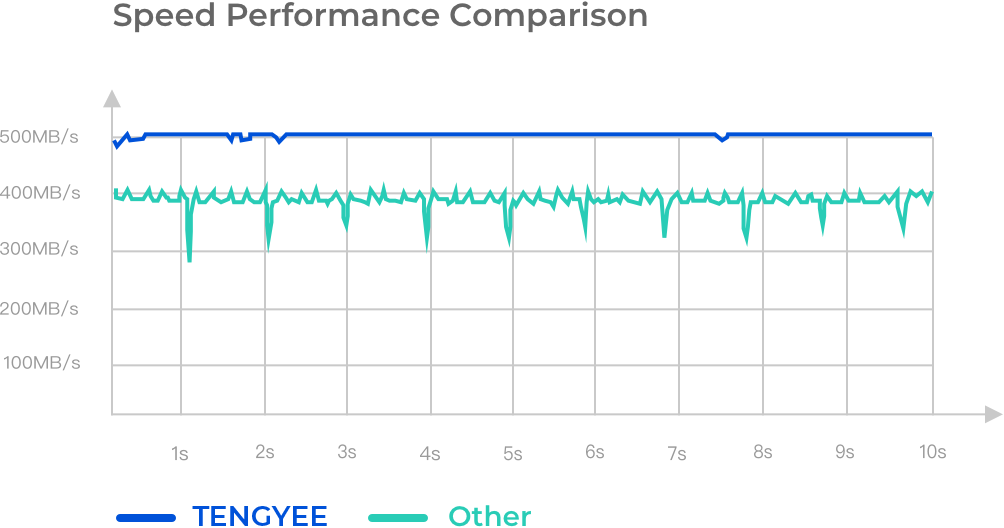

500 MB/sSequential performance up to 500MB/s

-

64 CEDesign with dual 32bit processor, 8 lanes 64CE NAND channels

-

FirmwareOptimize flash management according to industrial and industrial application scenarios

-

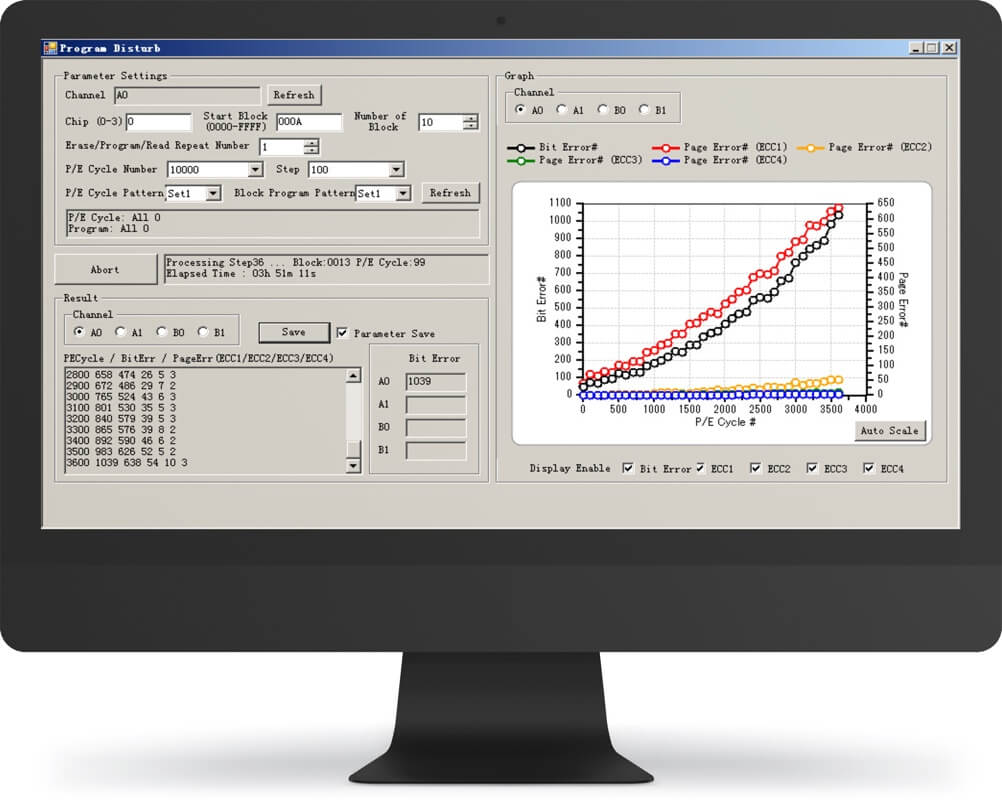

80 BIT/1KBEach lane supports 8CENAND and super ECC ability to 80bit/1KB

-

DDRSupport external DDR

Exclusive technology

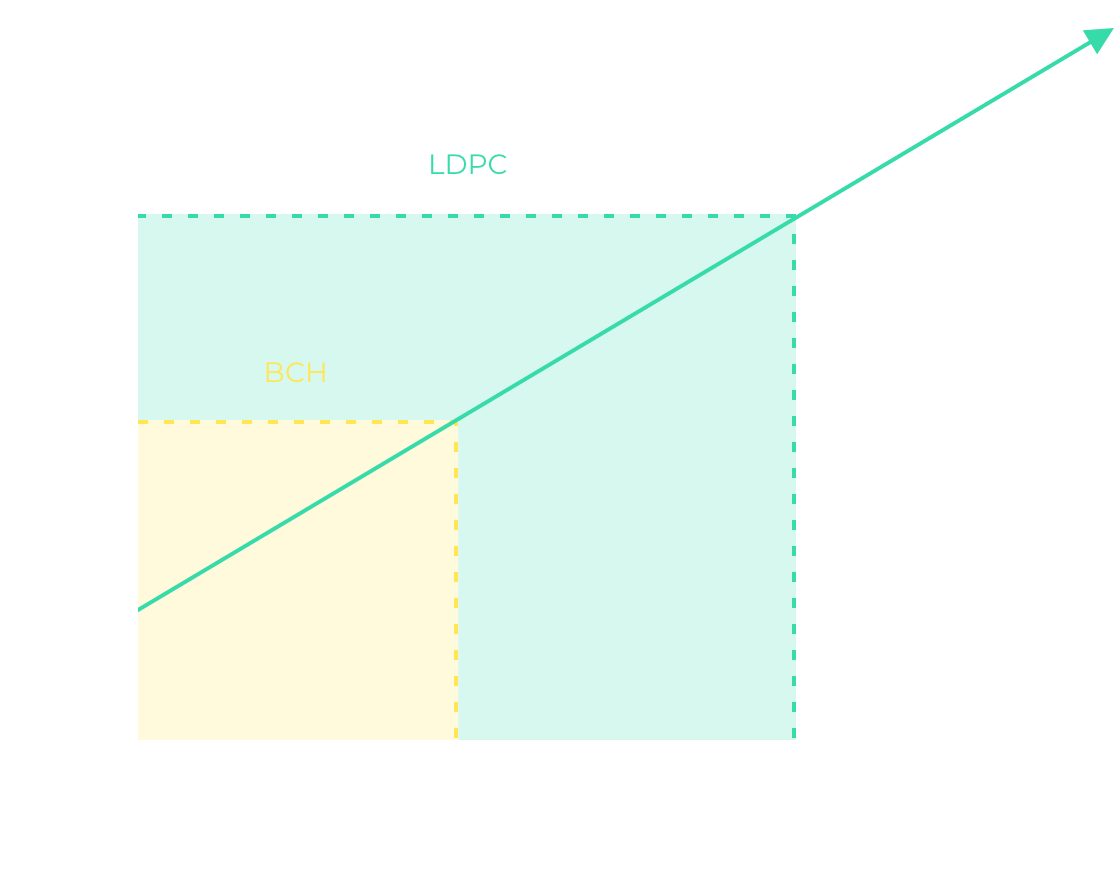

Powerful ECC Capability to Extend Lifespan of NAND Flash

Test Result of

Renice ECC & Normal ECC

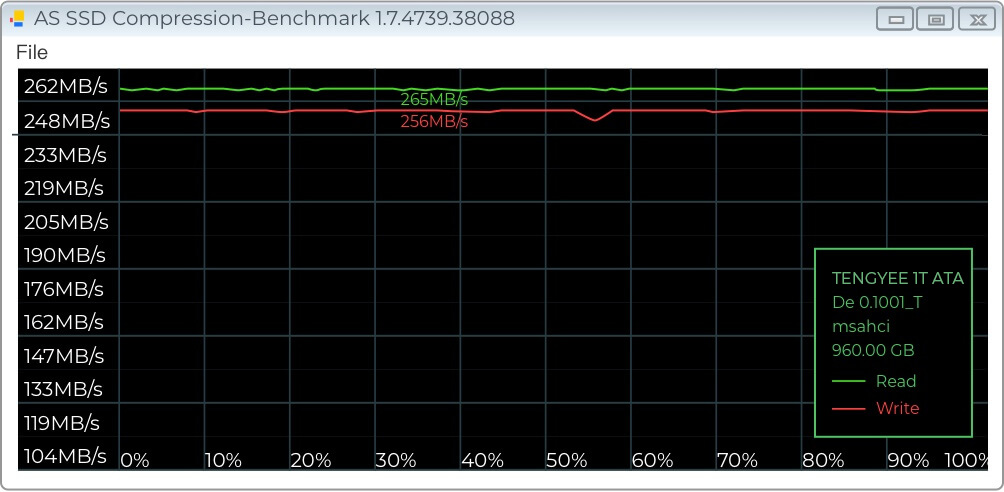

No Trim-Full Speed Performance

Global Unique Technology

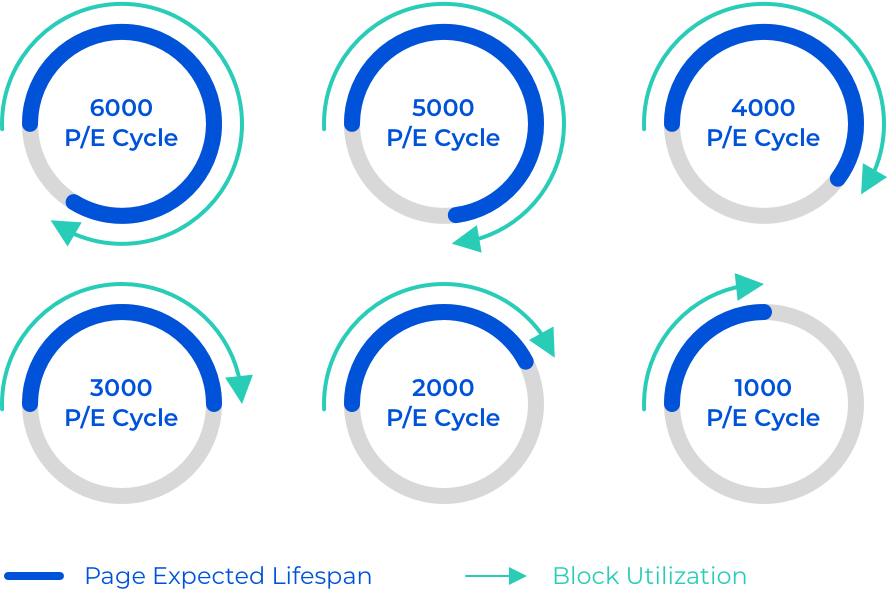

Non-Balance Wear Leveling TechnologyTM

Renice Non-Balance algorithm idea as: An able man is always busy

According to the actual P/E Cycle, the ability to achieve more.

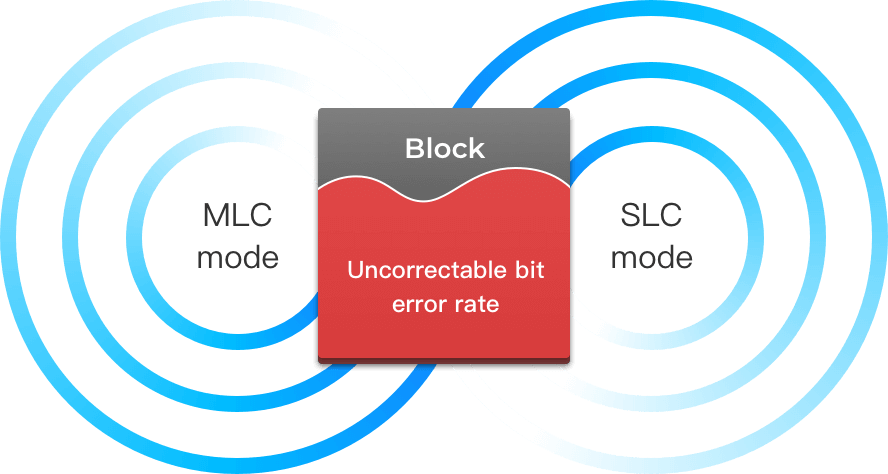

To extend lifespan via converting NAND mode based on the error threshold rate

MLC to SLC Technology

Stable Performance

PR-Latency Garbage Collection Technology

Performance not less than

80%

Proprietary technology

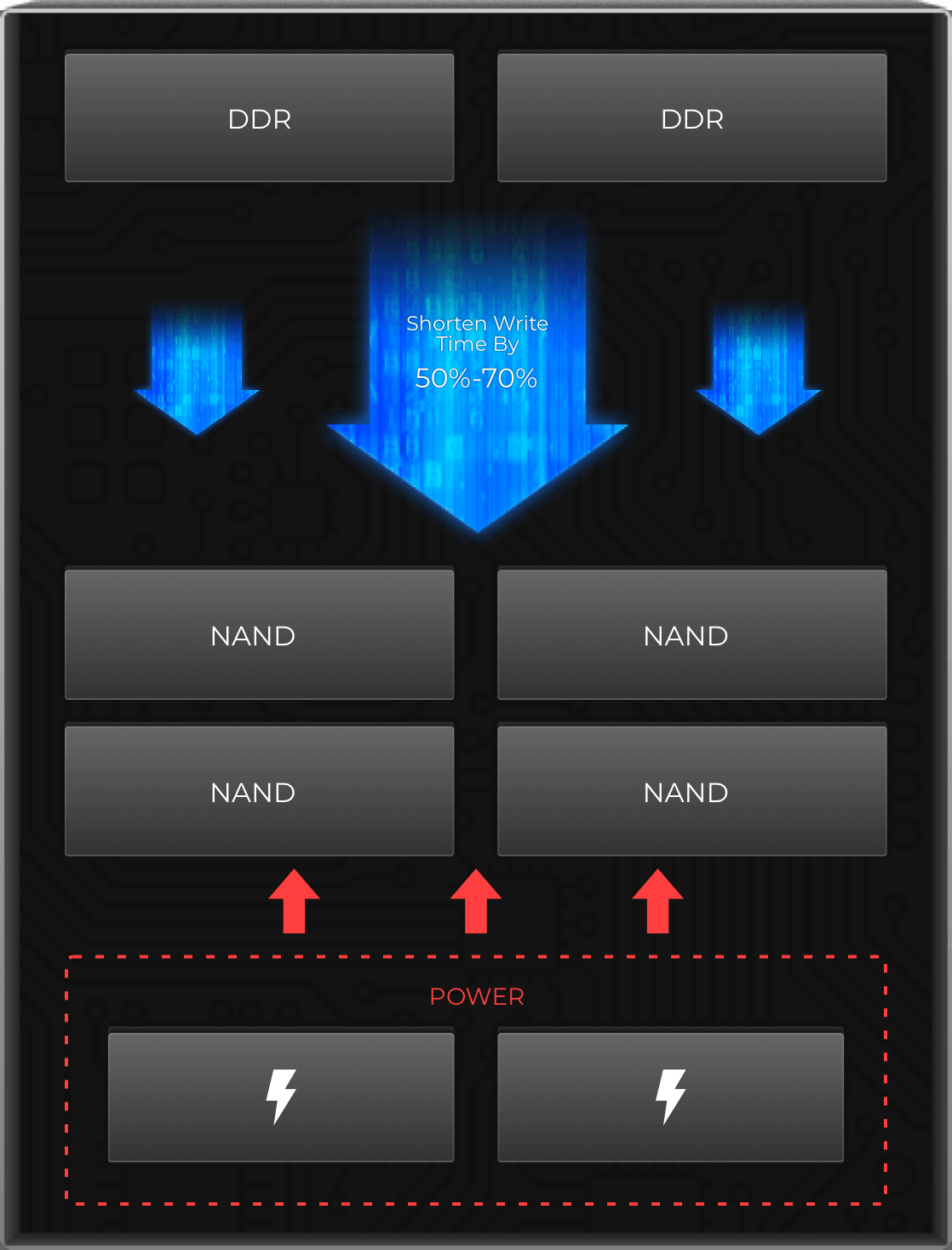

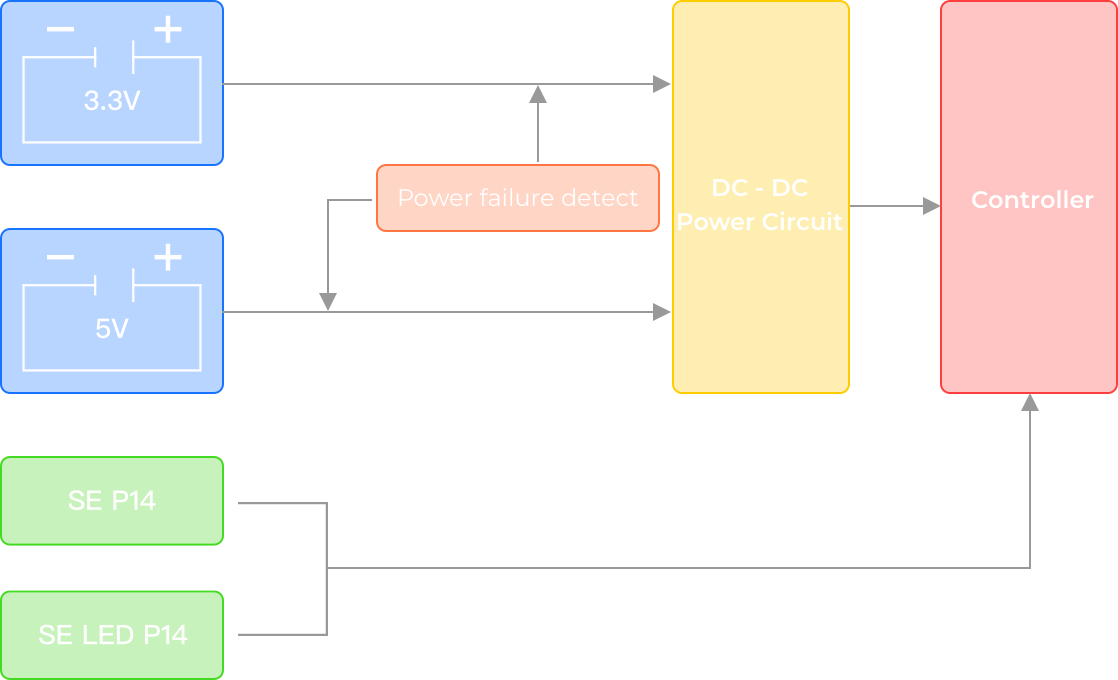

r-Backup Power Failure Protection

Shorten Write Time by

50%-70%

300,000 times Abnormal Power-off Test

0 Defect

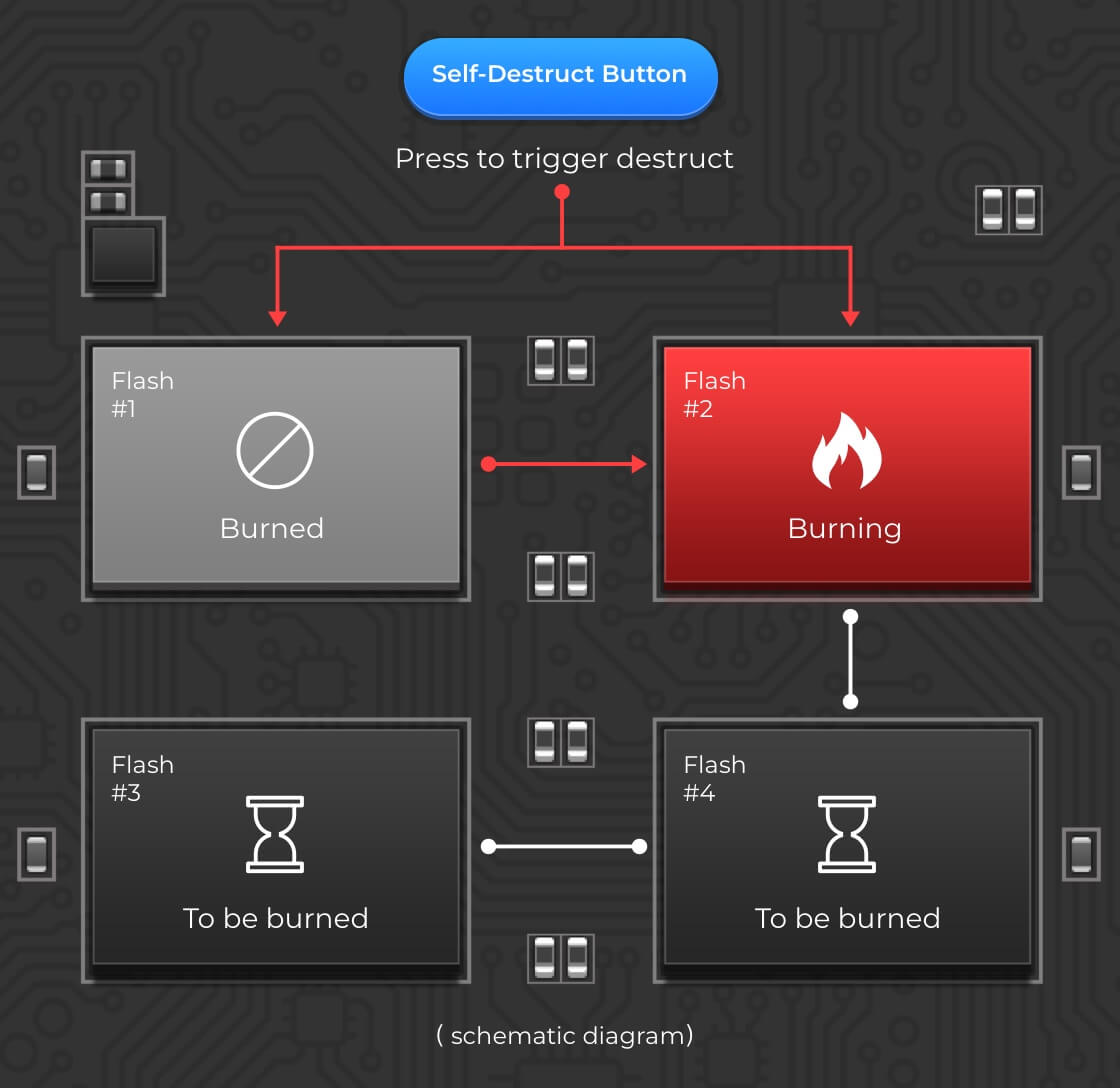

Customize Special Functions

Time-sharing Shunt

Burndown flash chips one by one by means of time-sharing shunt design, ensure all flash chips are destroyed

Burn-down in 100ms

Ensure to burn down the flash chips completely within 100ms. The burning time of entire SSD is adjustable

High Voltage Breakdown

Breakdown the flash chips through high voltage thoroughly to avoid data been recovered

Real-time Feedback

Unique circuit to achieve real-time monitoring of burning status.

5s False Triggering

Default with 5s false trigger time after power on. The time is adjustable.

False Trigger Prom

There will be warning lights when pressing destruct button in state of power-off

Exclusive technology

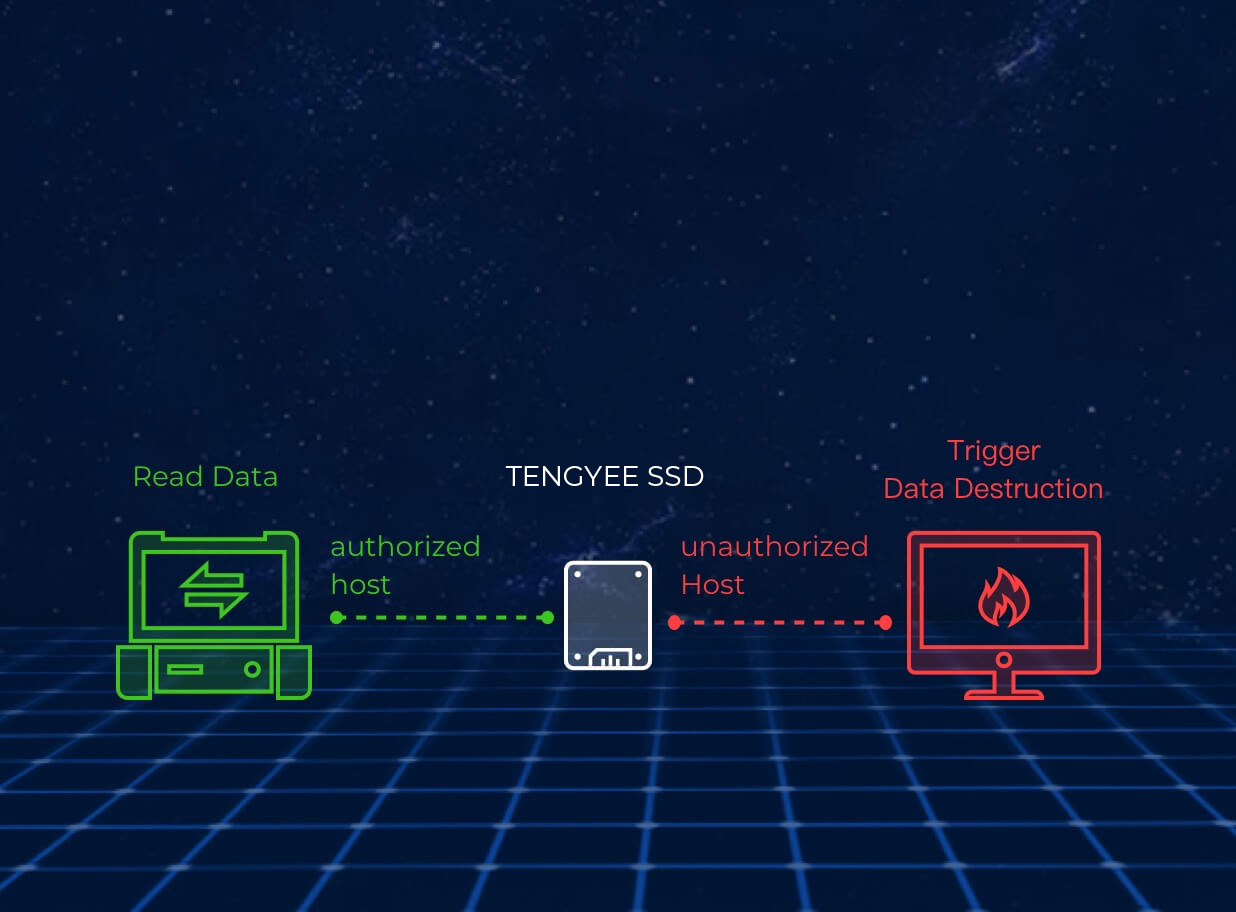

SSD Data Destruction Methods in industrial Applications

Physical Space Displacement

Connected with unauthorized Host

Acceleration Induction

Independent development

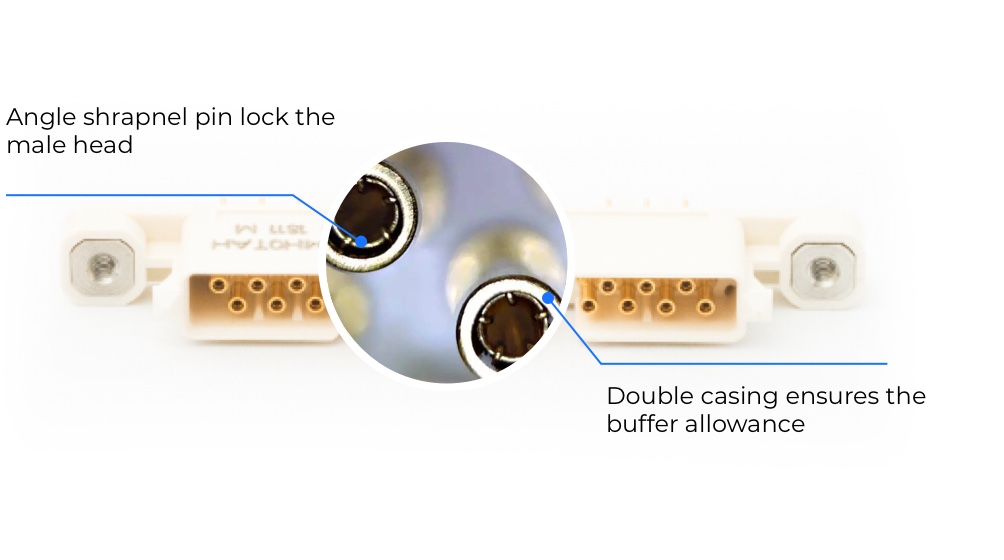

High Reliable Rugged SATA Connector

Strong Buffer Design

The rugged connector with special buffer structure between connector and PCB. Each Pin is designed with spherical at the bottom, to ensure rotation at the same angle and maximize the buffer effect in face of strong shock and vibration, therefore to avoid damage of connectors.

Mother Connector designed with Double Casing

Take into account of simple-swap, no poor contact and not damage the Pin, the mother-connector is designed with double casing to provide enough buffer. And the inner 5 spring strip guarantee full contact with male connector perfectly.

Independent development

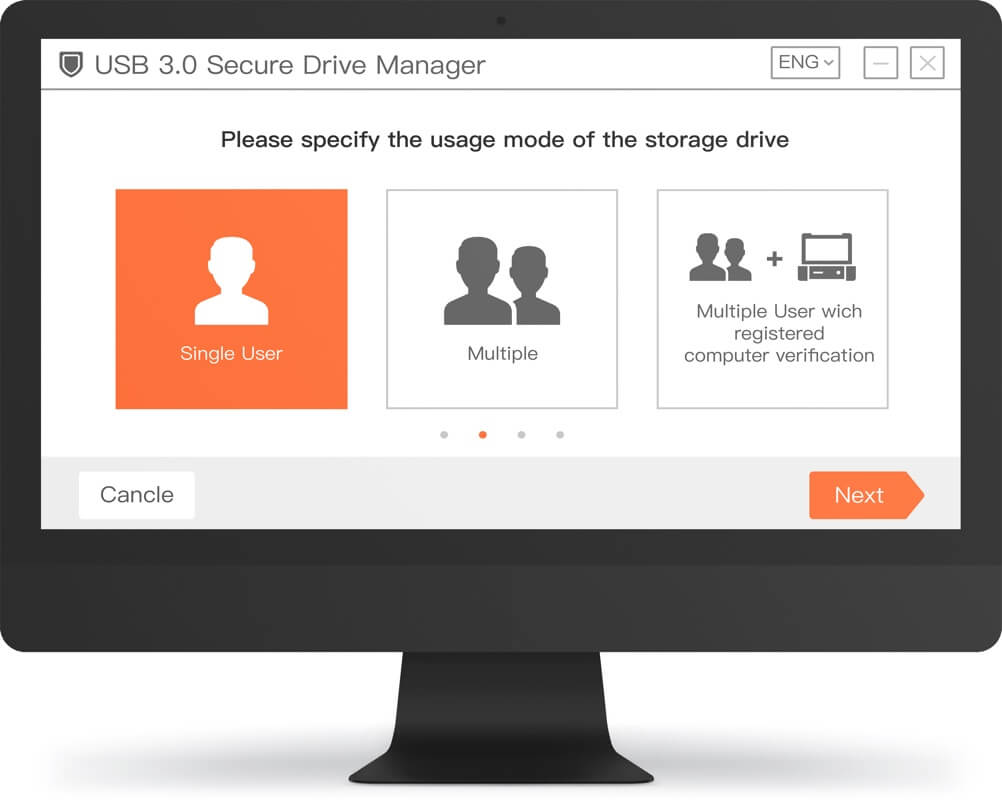

Software Encryption

AES Encryption

Perform Data Secure Erase under power failure

Secure Erase under Power Failure

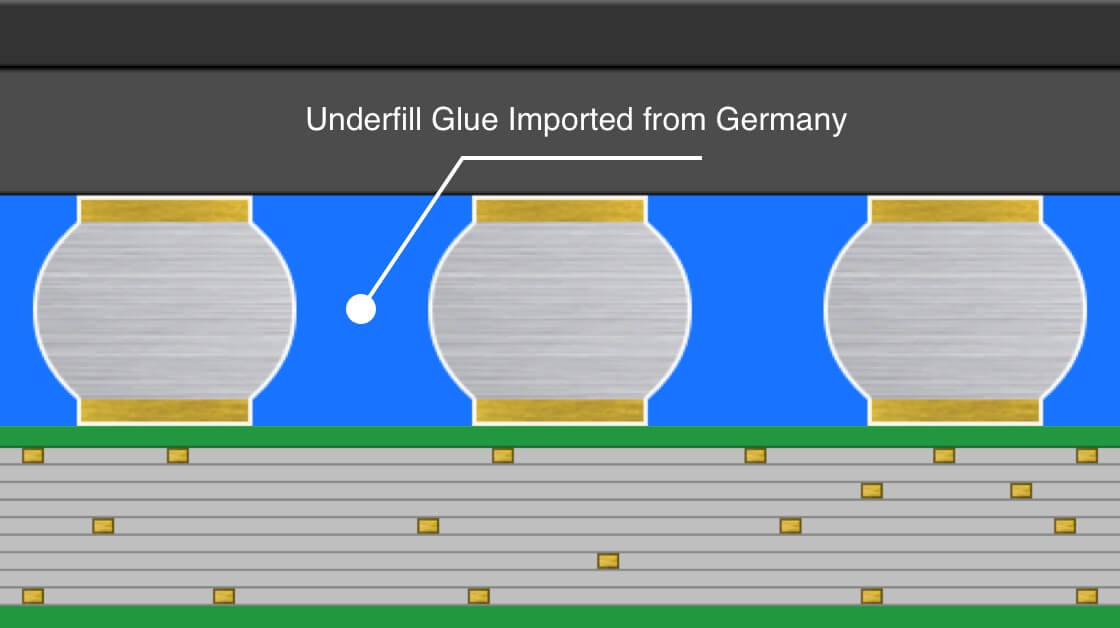

High Specification Production Process

Exclusive process

industrial Grade Materials, Strict Production Process

industrial Standard PCB

Conformal Coating Technology

Chips Reinforcement Technology

Key Processes

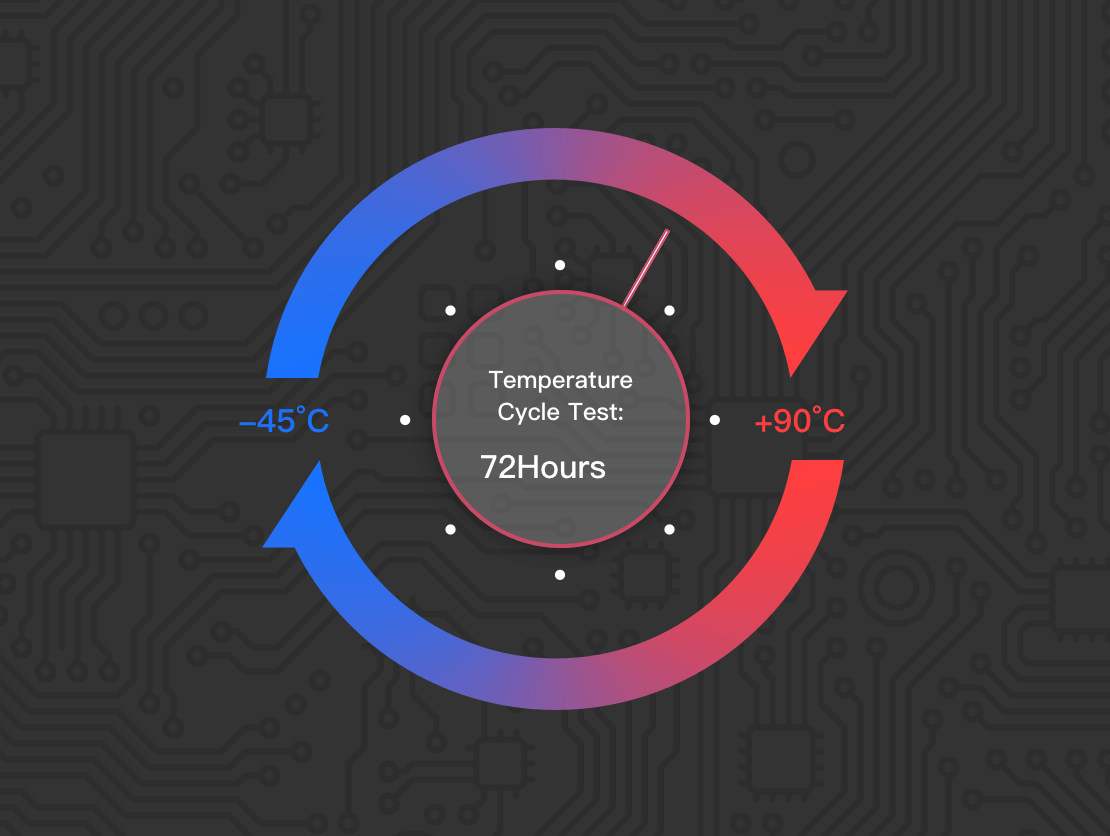

Strict High-Low Temperature Test

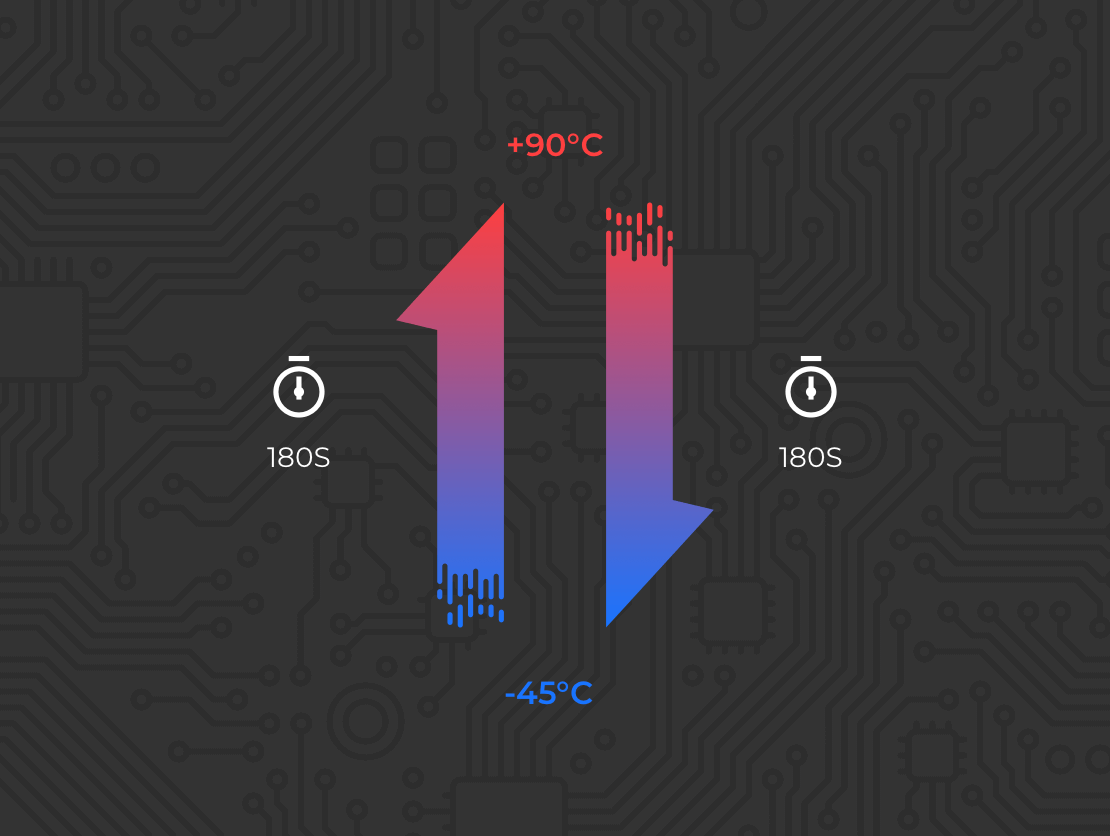

Temperature Cycle Test:

Products

Products