Renice SSD Temperature Test Procedures - Extreme Temperature Tolerance

Temperature test of industrial SSD products includes temperature cycle test and thermal shock test.

Note: Plenty of frosts turned to water drops in the transition process from low temperature to high temperature. The water drops may easily cause a short circuit of chip pins and thus burn the industrial SSD. Therefore, reinforcement and waterproof treatment have to be done on tested industrial SSDs.

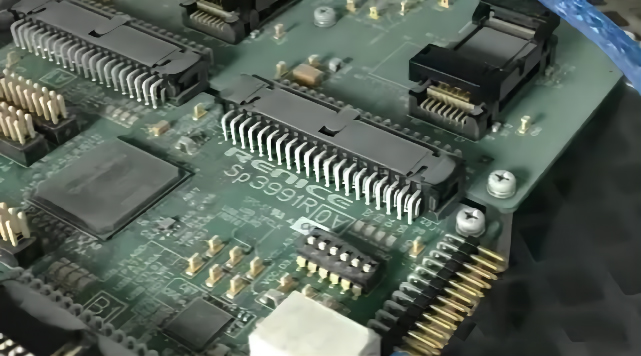

Picture of a tested circuit board with frosting surface under -40°C

Temperature Cycle Test of Renice SSD

The temperature cycle first set the temperature at -50°C and keeps for 4 hours, then rises the temperature to +90°C, keeps for 4 hours, and next lower the temperature to -50°C to finish one cycle. Do multiple cycles in turn.

The standard of industrial grade operation is -40°C to +85°C. Considering the temperature deviation of the high-low temperature chamber and avoiding the inconsistent test result on the customers’ side, Renice in-house test extends the temperature range at ±5°C based on the standard.

Test Procedures

1. Lower the temperature to -50°C under the state of power-off, and keep it for 4 hours.

Note: Do not execute the low-temperature test in power-on condition. Because the chipset itself generates a temperature above +20°C in power-on conditions, it is normally easy to pass the low-temperature test. So getting the disks completely chilled is necessary before testing them in a power-on state.

2. Power-on and run read/ write performance test on SSD, to compare the performance at normal temperature.

3. Aging test, to check if there is an error created.

4. Power-cycling test.

5. Rising temperature up to +90°C and keep it for 4 hours. Contrary to the low-temperature test, the process of the high-temperature test is done in a power-on state to keep the inside temperature of the chipset in the high state. And then executing steps 2, 3, and 4 after 4 hours.

6. Repeat 10 times of high/low-temperature testing separately.

The test is judged as fail if any abnormity detected during the test.

In the current market, there is a common situation that screening the commercial-grade products for industrial-usage, while there could be risky. The screened products may have a high probability of failure in several temperature cycles. Besides, they cannot pass the strict extreme temperature test or pass the test one time but failed in next time.

Thermal Shock Test of Renice SSD

The thermal shock means the quick transition from low temperature to high temperature in a few minutes (or customer time) and the high temperature to low temperature.

Normally the test starts from low temperature, which changes from -50°C to +90°C less in 3 minutes, or use the same method to start the test from high temperature.

During the temperature transition, Burin-test can be run all the time to inspect if there will be data comparison error during such a quick temperature transition.

The specific test standard can refer to: GB/T 2423.34, IEC 60068-2-38, GJB150.5, etc.